Overview

Our Vehicle Maintenance System is a workshop management package specially designed for coach, bus and truck operators. The system is in daily use with over 600 operators.

The software provides defect reporting, statutory inspection planning, scheduled and unscheduled maintenance activity management, job cards, history recording and workshop control. VMS streamlines the whole process and helps ensure records always meet the required standard.

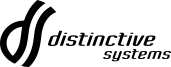

Vehicles

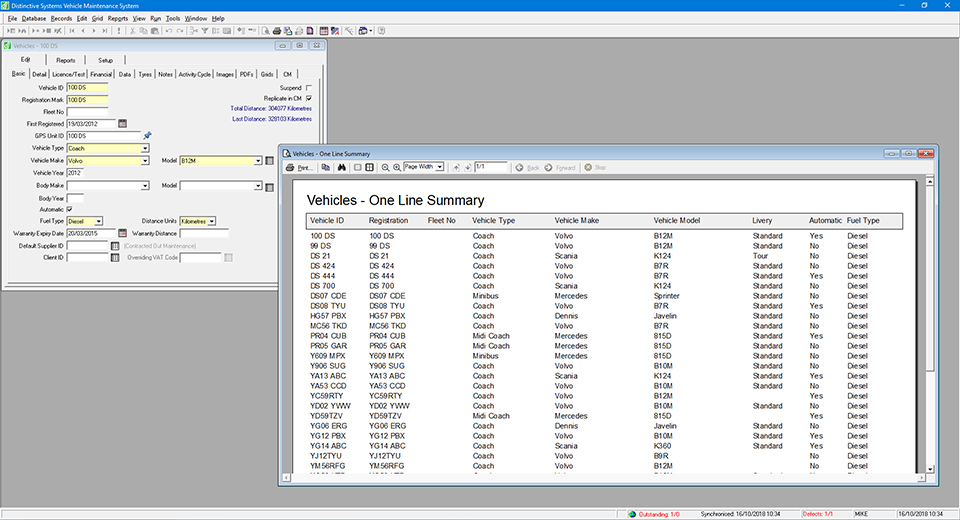

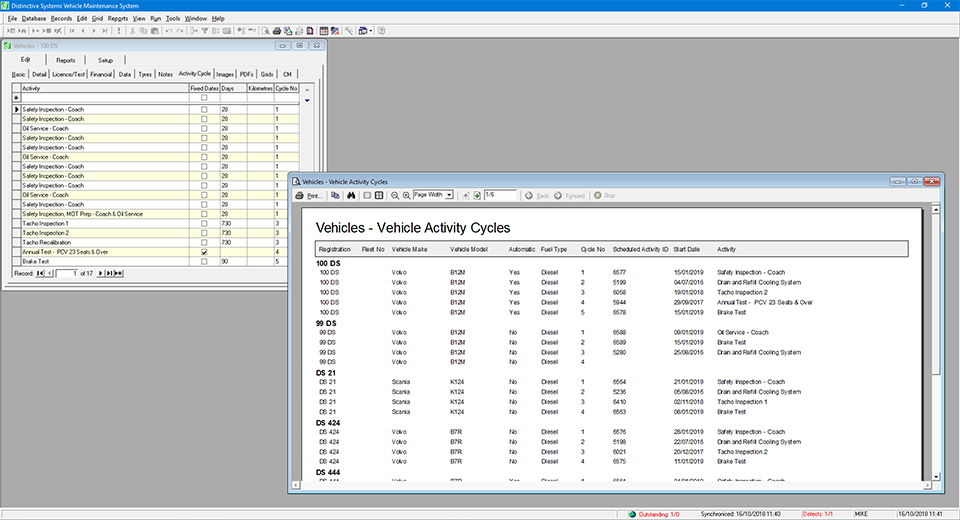

Comprehensive details of each vehicle can be entered in to the system which includes the vehicle make and model, licence information and test dates. User definable maintenance and inspection activities are assigned to the vehicle. Activities can be planned for each vehicle. These are then grouped in to user definable cycles to ensure they are performed in the correct order. Each activity can be carried out based on a set time interval and/or distance reading, alternatively they can be set to a fixed date.

Details of specific tyres can be added to a vehicle including the axle and tyre positions. Individual vehicle details of reported defect and nil defects, fluid usage, accidents and incidents and unavailable dates can be reported on. The integration with Coach Manager ensures allows vehicle records can be replicated without requiring manual re-input.

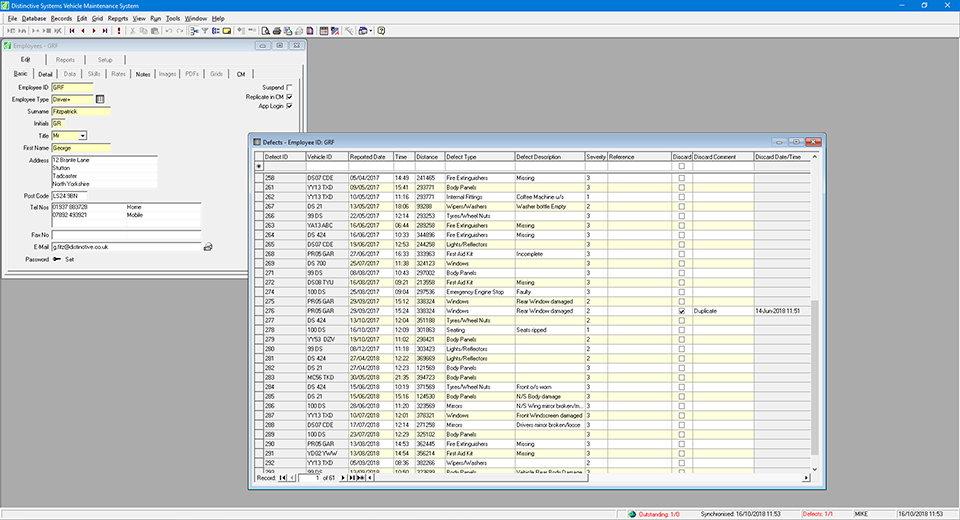

Employees

Details of each employee can be created in VMS or details can be replicated via the integration from Coach Manager. User definable skills and hourly costs can be defined per employee to optimise allocation of staff to activities through the workshop planner and to automatically apply labour rates for costing purposes. For an individual employee you can view all nil defects, defects and fuel usage entries. Holidays, rest days and sickness etc can be managed through the employee log.

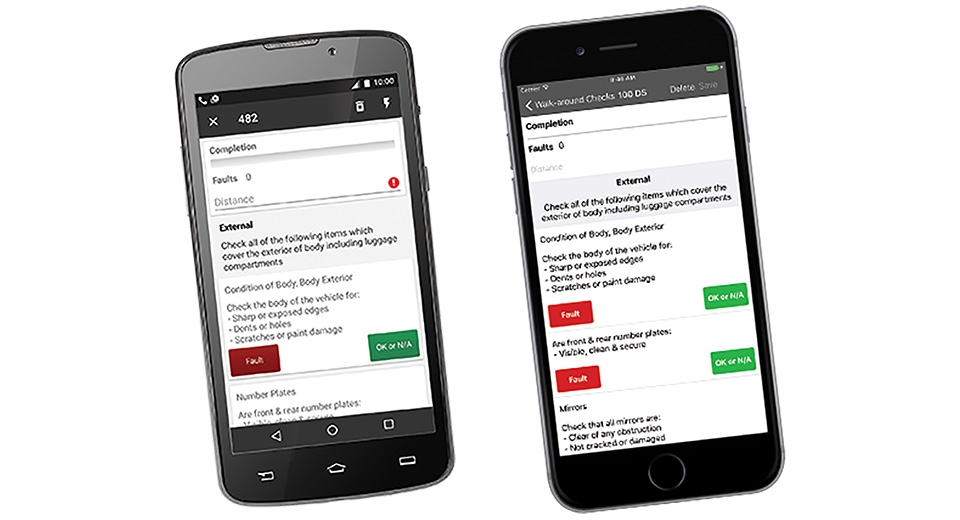

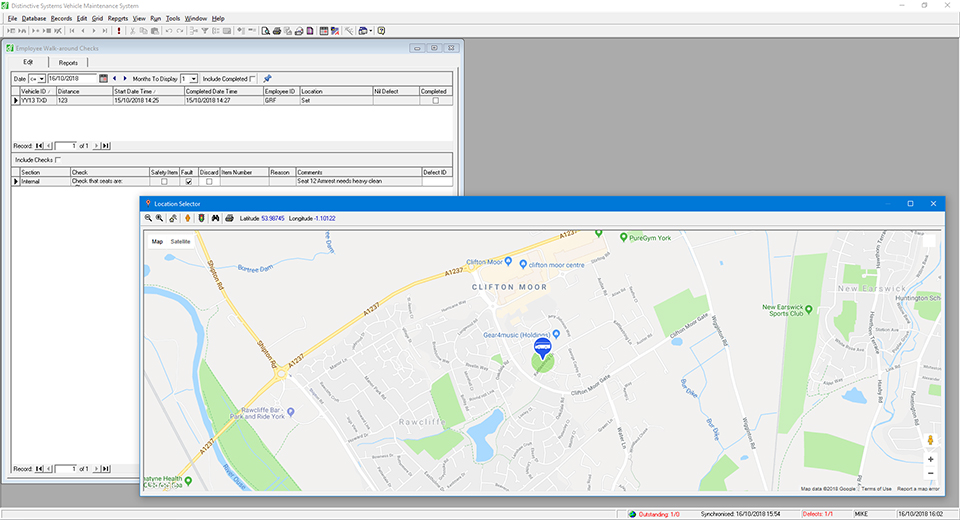

Walk-around Check Mobile App

Our award winning Driver Walk-around Check Mobile App is fully integrated with VMS and complies with all statutory walk-around check and defect reporting requirements.

The app makes it easy to ensure drivers comply with their statutory duty to carry out a daily walk-around check and report any defects found. It guides the driver through the complete process for performing the walk-around check. Against each item to be checked the driver can touch a green button to say it is OK, or a red one to report a defect.

When a defect is found the driver can choose from a list of predefined common defects, or enter a free type description. Up to four supporting photographs can also be included.

The completed walk-around check results include the date and time it was carried out, the time taken to complete it, the vehicle distance reading and the GPS location at which it was done.

The app is available for both iOS and Android devices.

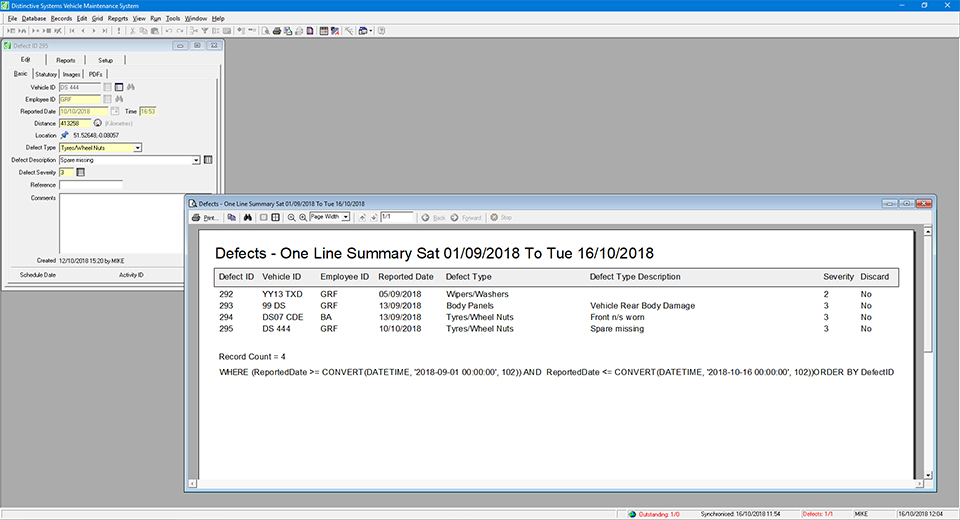

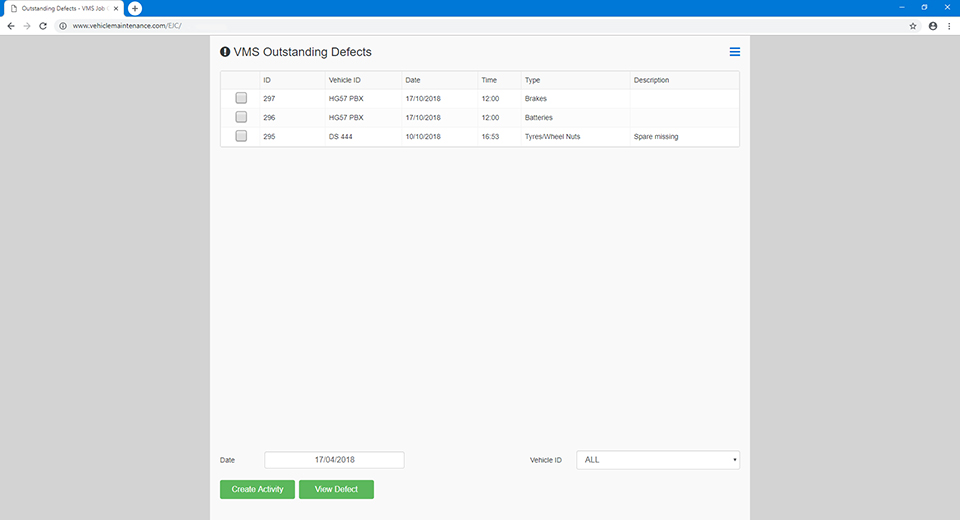

Defect Reporting

The defect reporting system allows user definable defect types, stored common descriptions and a full implementation of the statutory reasons for failure to be used to record defects reported by employees. Images and PDF documents can be stored against a defect record and an indicator on the task bar highlights the number of outstanding defects and the number of uncompleted defect related activities.

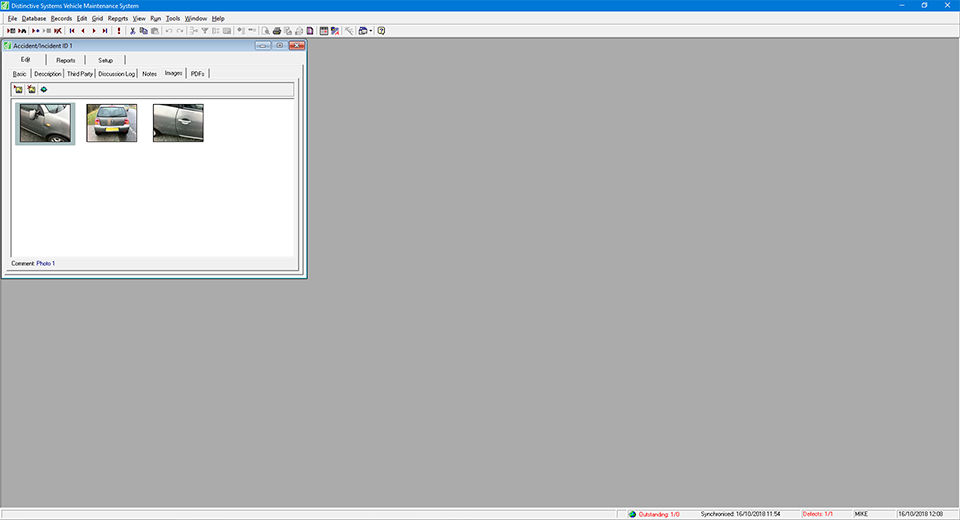

Accidents and Incidents

Accidents or incidents can be managed through VMS including the ability to record a detailed description of any damage together with third party information where appropriate. A discussion log is provided to record a timeline of events and images and PDF documents can be stored against each incident.

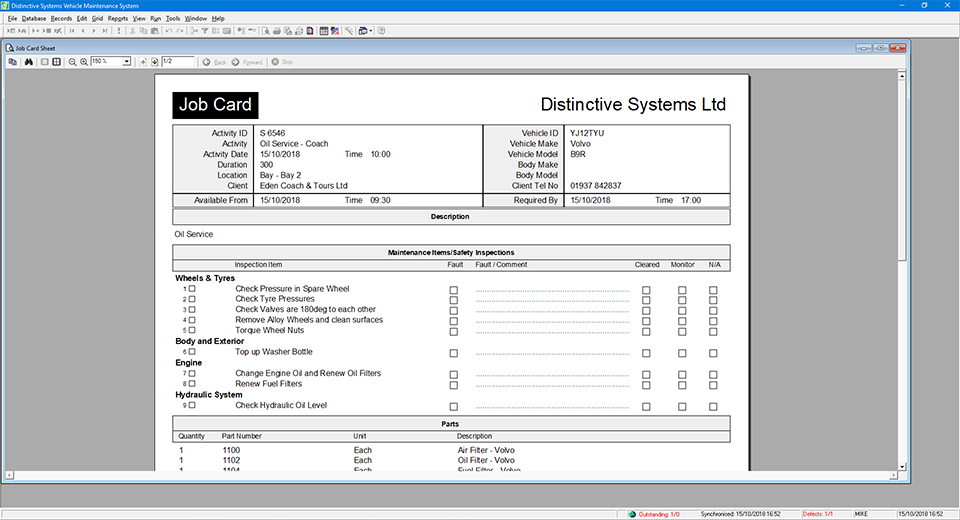

Activities and Job Cards

In addition to ensuring proper control of all statutory safety issues, VMS also provides a complete solution for operators looking to manage the maintenance of their vehicles for maximum efficiency and longevity in accordance with manufacturer's recommendations. The system allows operators to create their own scheduled maintenance activities each consisting of an unlimited number of user definable planned maintenance items. The activity cycle for each vehicle can be controlled by distance, days, hours or fixed date. Activities can either be scheduled individually or automatically up to any future date.

Unplanned activities such as breakdowns, defect repairs or accident damage can be managed by creation of unscheduled activities. These activities can be created at any time and can either be assigned to their own date and time, or, depending on urgency, be attached to an existing scheduled activity.

Job cards with user definable layouts and content can be printed or emailed automatically for each activity for a specified date.

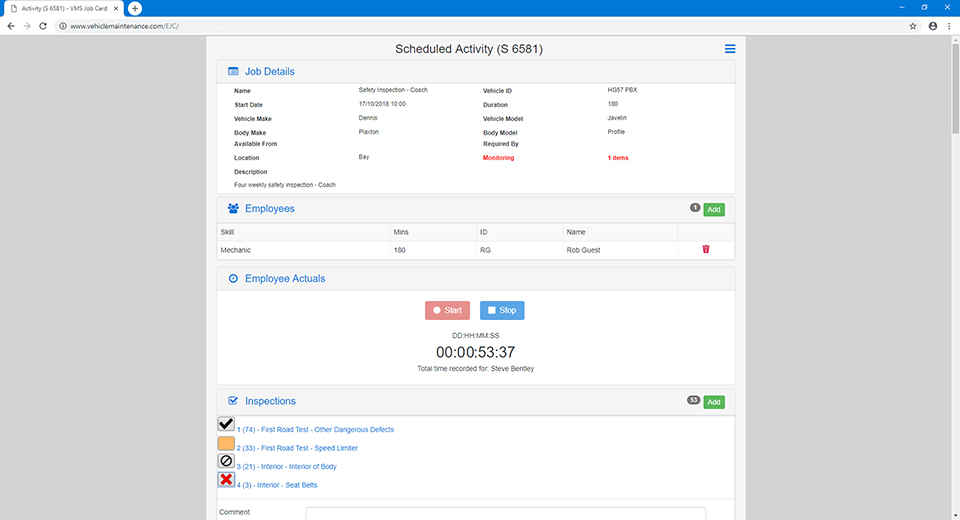

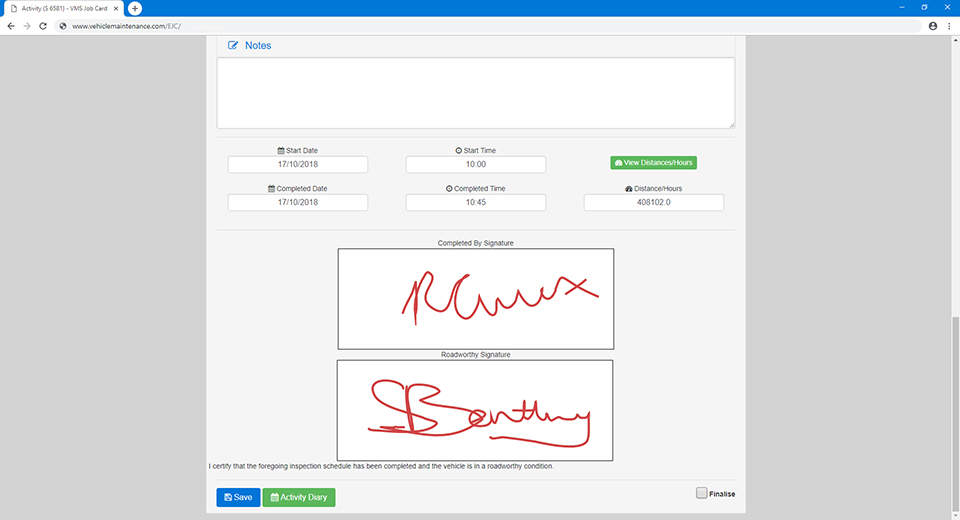

Electronic Job Cards

The Electronic Job Card not only allows your workshop to become paperless, but also goes way beyond what can be achieved with the original paper document.

The job card is implemented as a web page running in a browser on a laptop or tablet device. Inspection and maintenance items can be ticked off as they are completed plus any faults and work done can also be recorded item by item.

Costs incurred, parts used, additional work, notes, brake test results and PDFs can be recorded directly into VMS from the electronic job card. It also records start and completion dates and times, and can be signed off electronically.

The electronic job card is hosted on your existing in-house network. The only cost you will incur is for the installation of an ordinary wireless access point in your workshop.

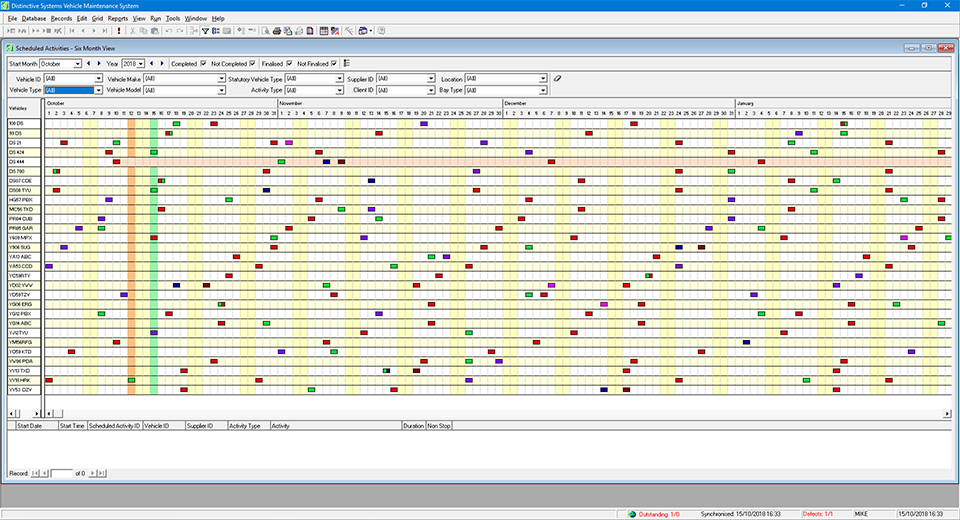

Six Month View Planner

The system automatically generates a six month view of scheduled activities which emulates the traditional wall planner. Filters are provided to include showing activities for a single vehicle, vehicle types, vehicle makes, vehicle models, suppliers, activity types, locations and bay types as well as the usual base, completed and finalised filters. A scheduling wizard allows the criteria for future activity dates to be determined.

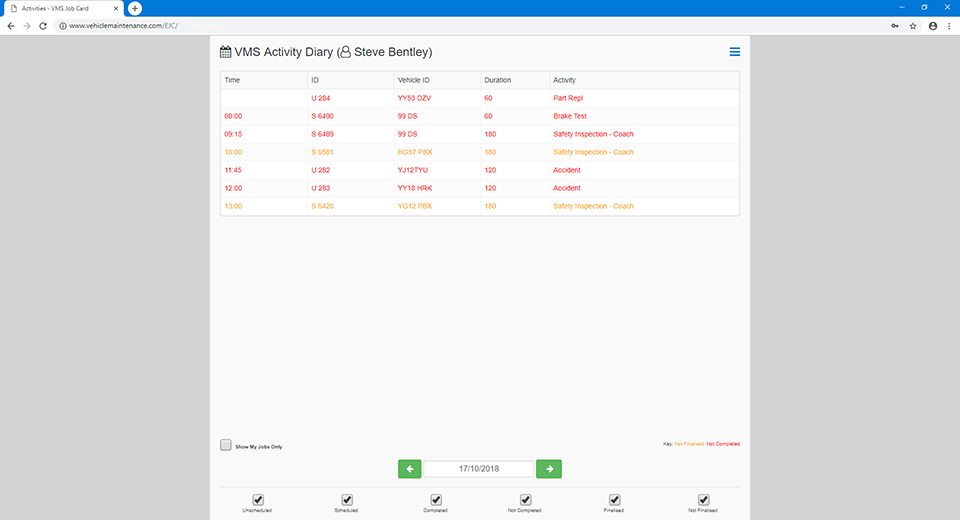

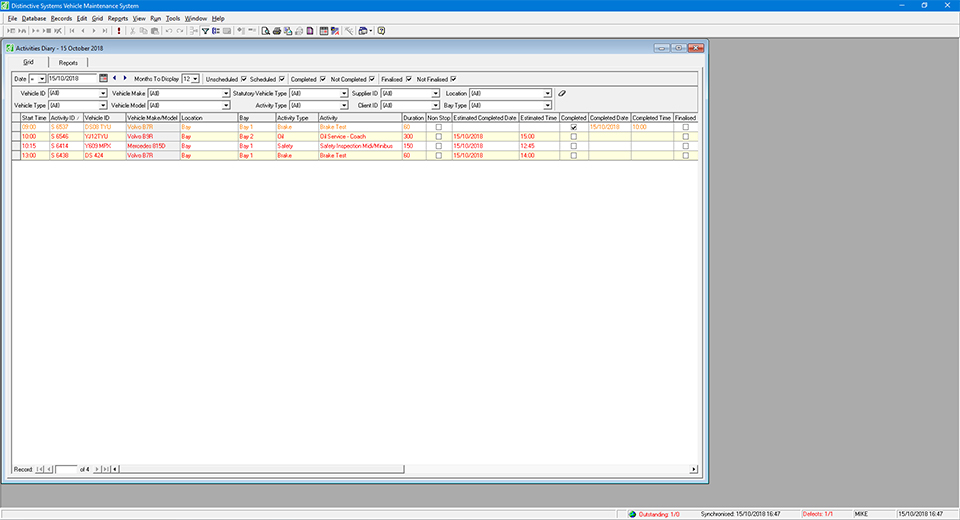

Activity Diary

The activity diary has the capability of showing activities in both the future and in the past. A wide variety of filters are available and include showing activities for a single vehicle, vehicle types, vehicle makes, vehicle models, suppliers, activity types, locations and bay types as well as the usual base, unscheduled/scheduled activities, completed and finalised filters.

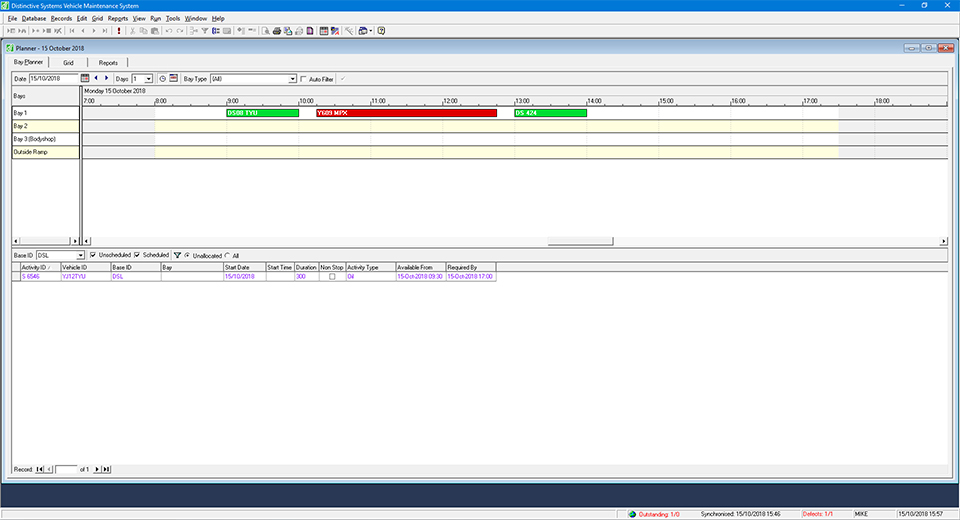

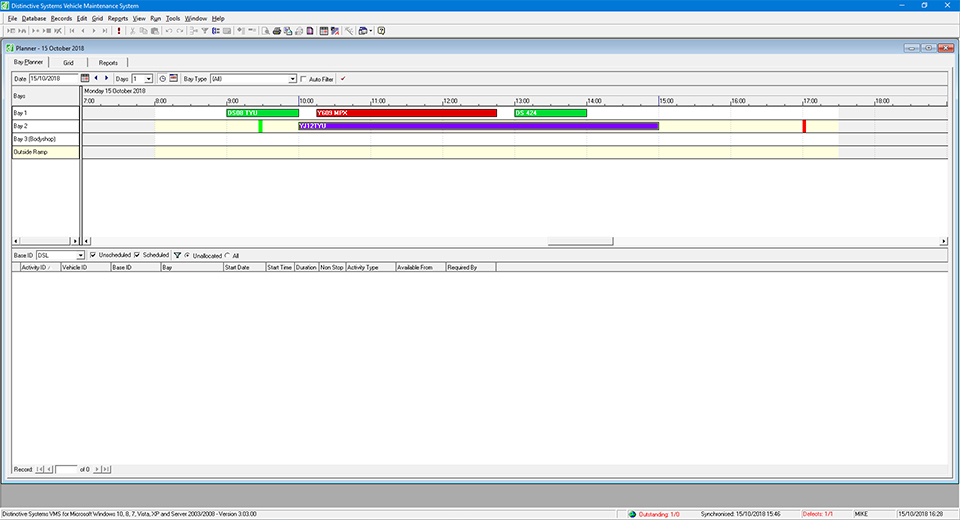

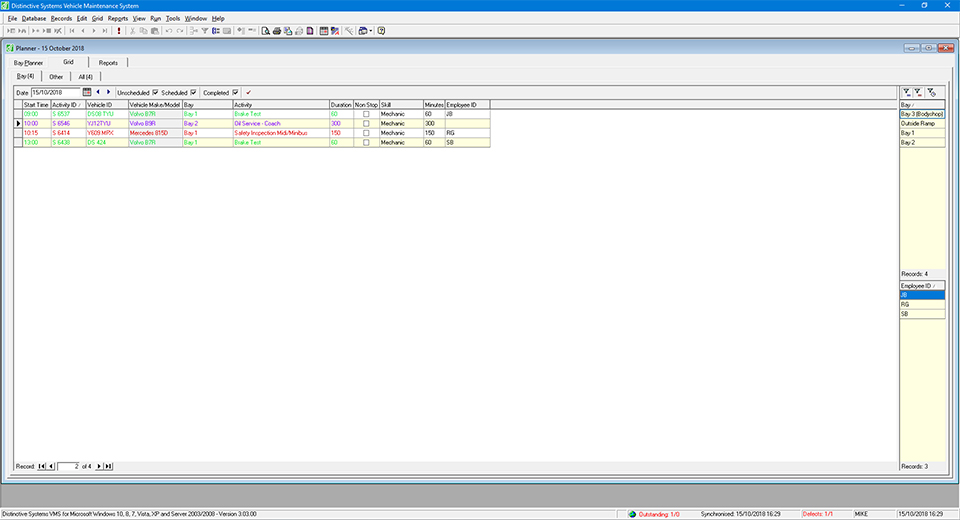

Workshop Planner

The highly visual bay planner has a drag and drop facility to allocate activities into user definable bays. Bay Types and Facilities can be defined and filters are provided to ensure that an activity is allocated to a correct bay type and facilities. The start time and estimated completion of each activity is automatically calculated and updated. Employees can also be allocated with filters provided to assist with the best match of employee to skills required for the activity and they will highlight staff who are unavailable on any given date.

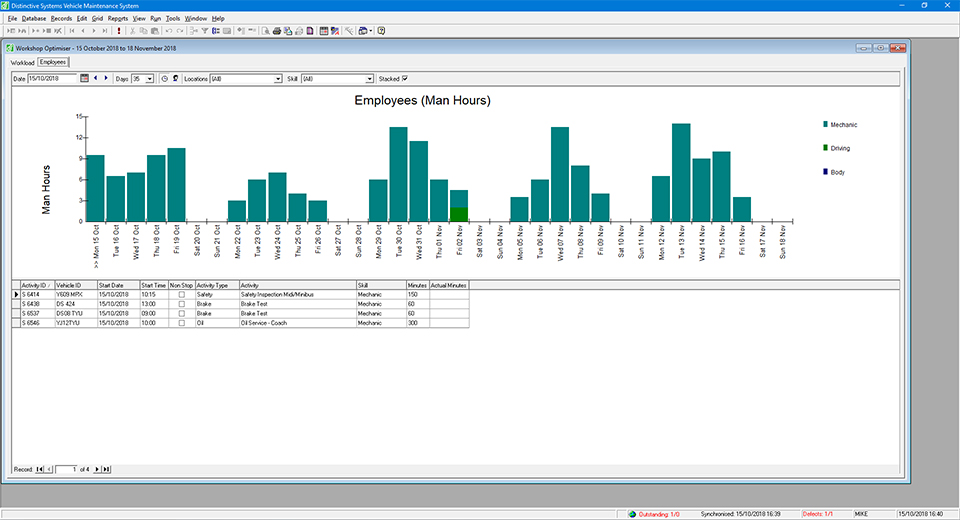

Workshop Optimiser

The graphical workshop optimiser facilitates the smoothing of daily workloads with automated rescheduling of subsequent activities. Workload can be measured in a number of ways including the amount of activity hours, the number of vehicles or the number of activities scheduled for the day. Employee workload can also be managed via the optimiser.

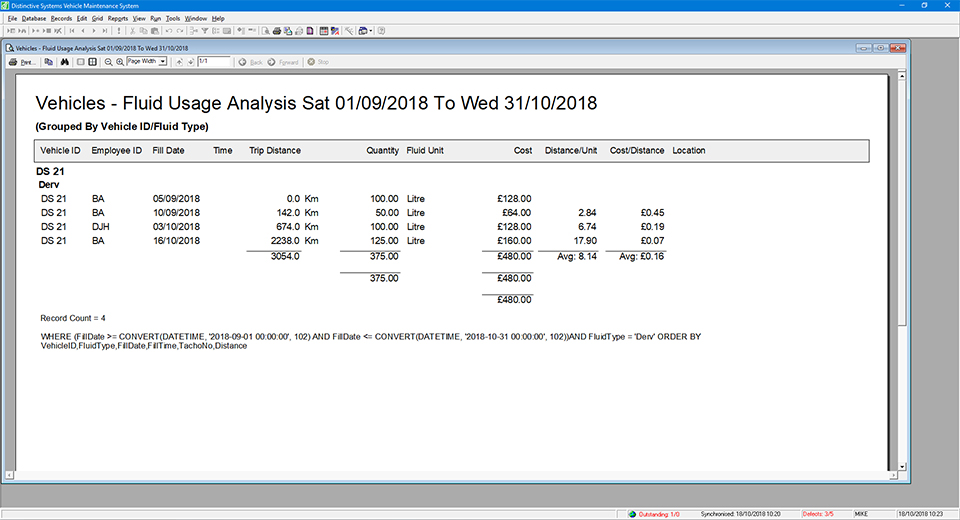

Fluid Usage

User definable fluid types can be created within the system and then each time the vehicle is filled the fluid type, amount, cost and employee can be recorded. Fluids can also be issued and recorded from the optional stock control module. Fluid type usage can be displayed for a specific vehicle and analysis reports, grouped by vehicle id or fluid type can be generated to illustrate quantities used, cost and cost per distance unit.

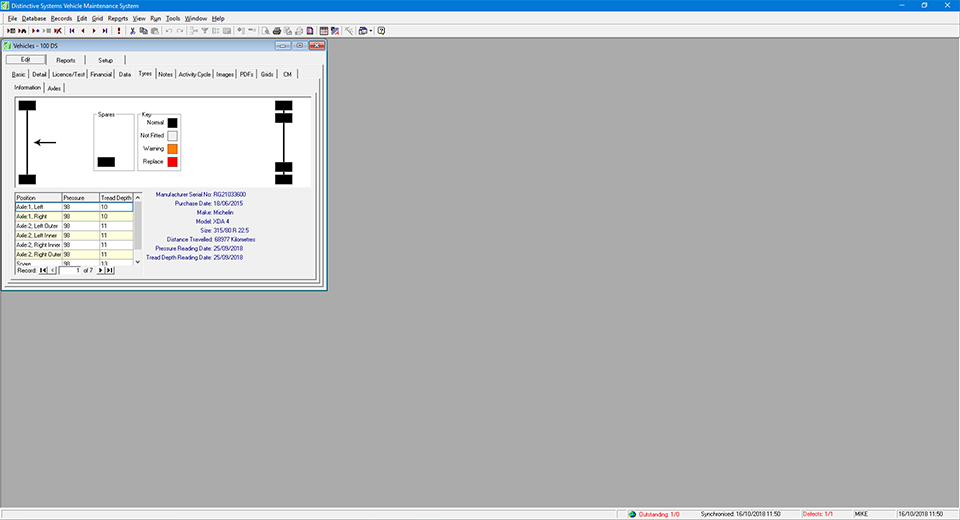

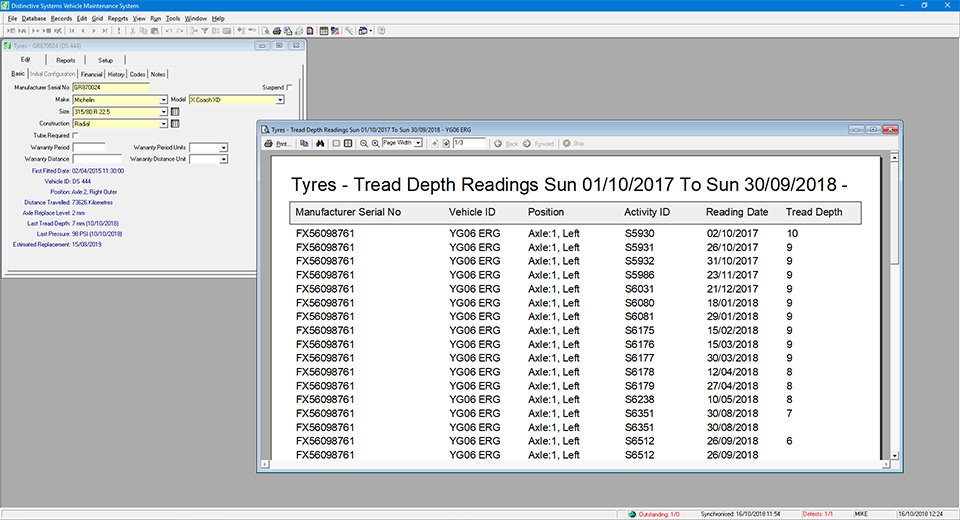

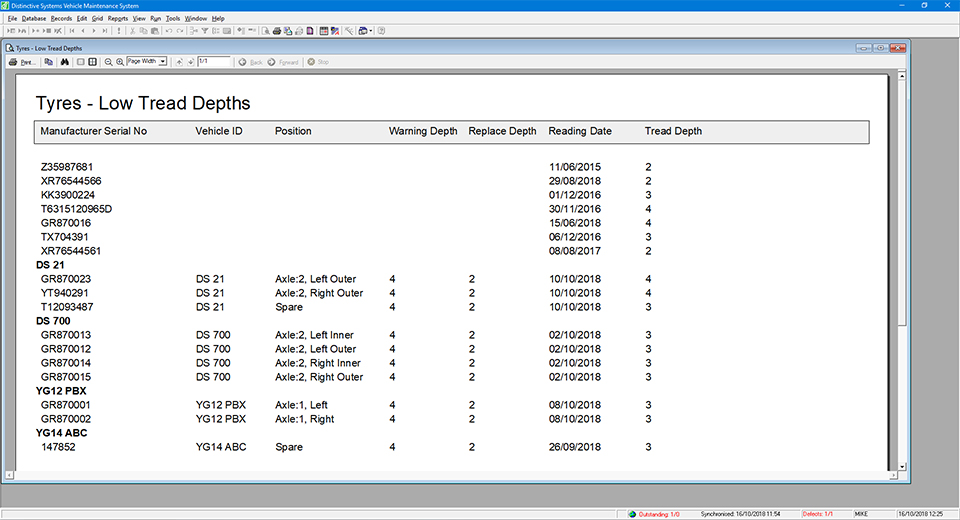

Tyre Management

The tyre management module has been designed to manage the maintenance and history recording of individual tyres fitted to vehicles in the fleet. The position of a tyre can be recorded including the axle and wheel position so that a tyre can be tracked and easily located. The module is fully integrated with both scheduled and unscheduled activities to allow tread depths and pressure readings for each tyre to be recorded quickly and efficiently. The system will predict when a tyre will require replacement and an overview of the last tread depth and pressure readings is provided for each tyre.

Comprehensive reporting facilities provide a history for each tyre including distances travelled, last tread depth readings, abnormal pressure readings and low tread depths.

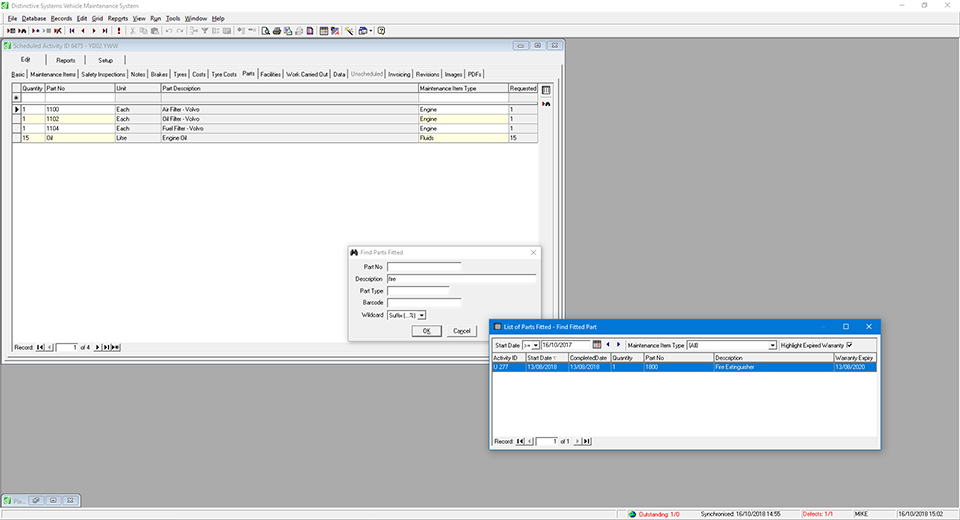

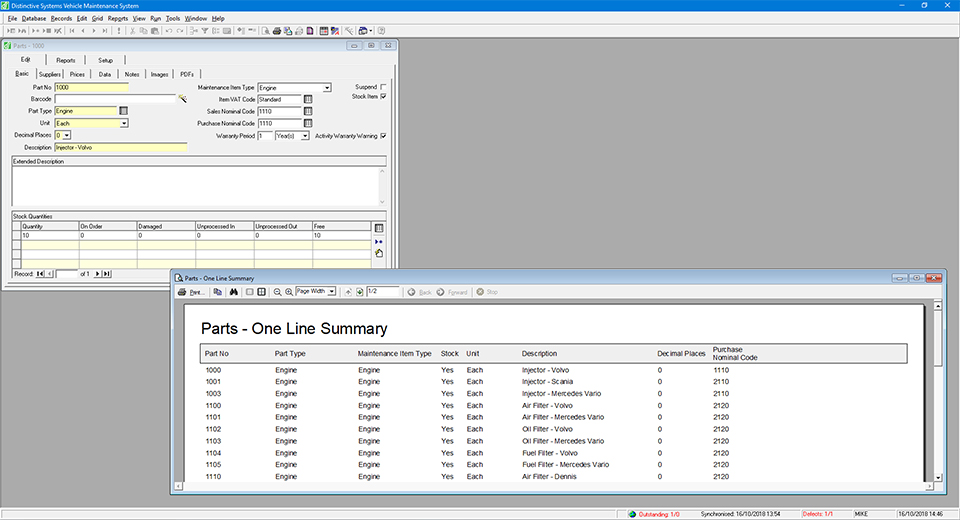

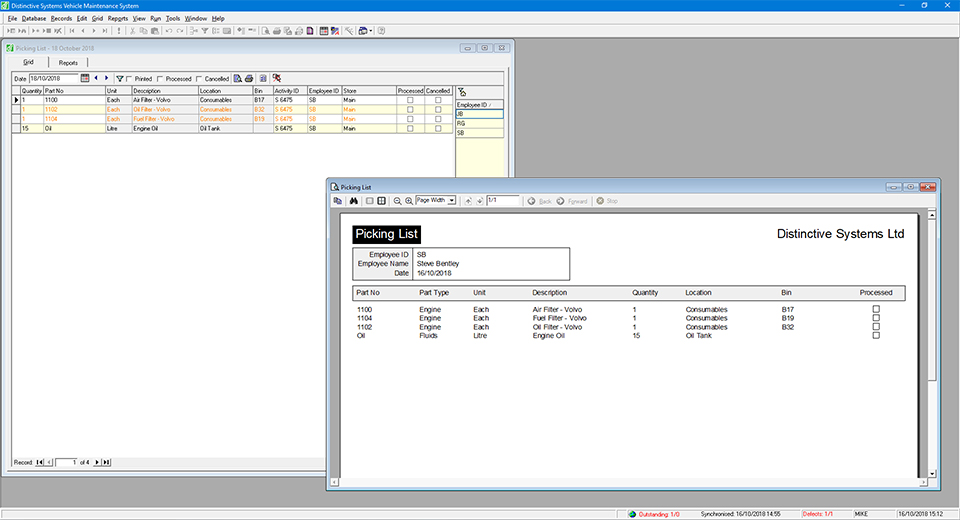

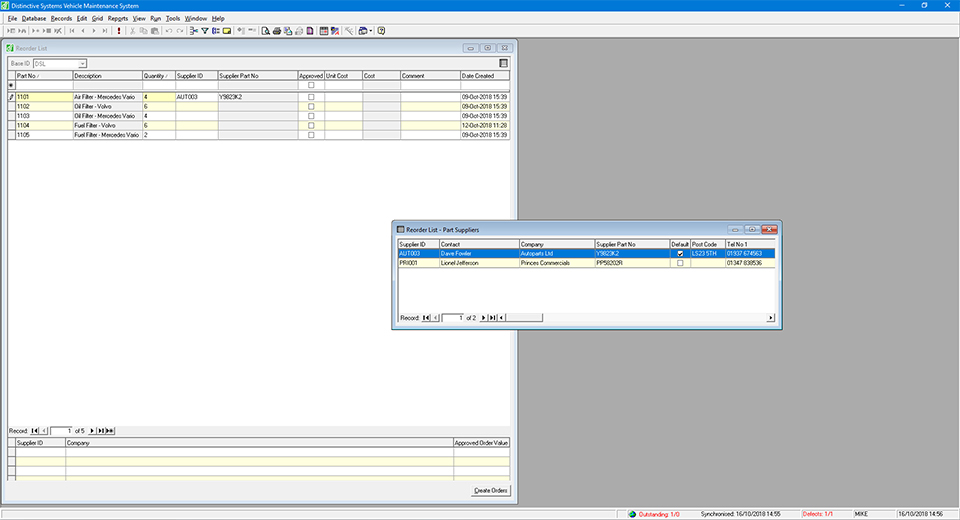

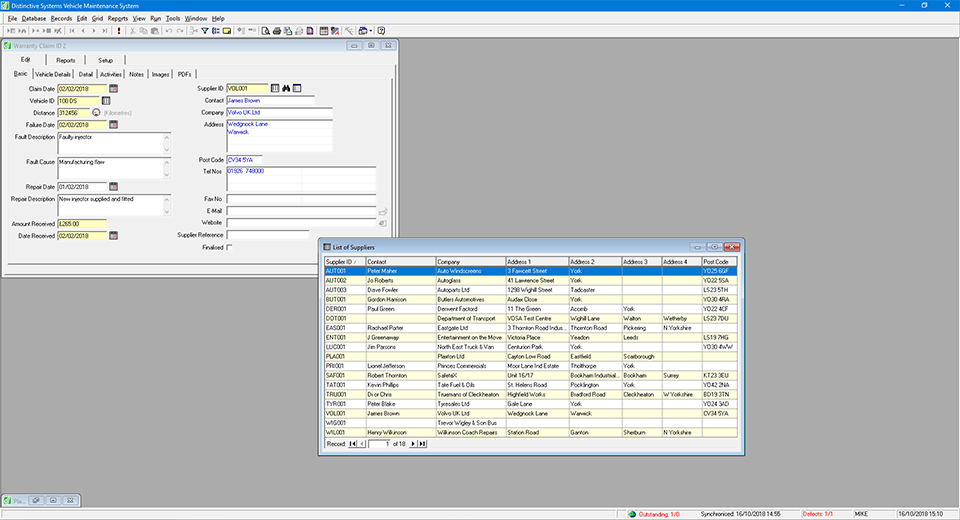

Stock Control and Warranties

Our optional stock control module is seamlessly integrated into both scheduled and unscheduled activities in VMS. The default parts manifest for each maintenance activity can be created in advance and is then applied automatically as each activity is assigned to a date. As each date approaches the system automatically generates stock movements for the required parts raising supplier orders as required. Additional parts can be added to both scheduled and unscheduled activities as required. The module also includes a comprehensive system for the efficient management of warranty claims.

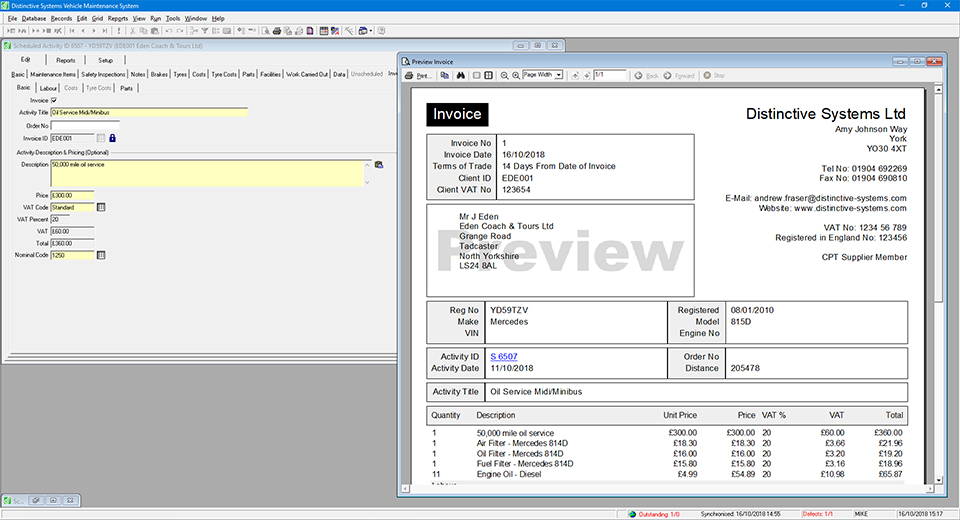

Invoicing and Sales Ledger

The optional invoicing module has been designed for clients operating a commercial workshop and is also fully integrated with both scheduled and unscheduled activities. The system can accommodate menu pricing of maintenance activities and can invoice parts, ad hoc items and labour. The module also includes a free entry invoicing system that can be used to invoice items not directly associated with maintenance activities.

Invoices can be generated automatically from the underlying activity details with clients being invoiced daily, weekly, monthly or on demand according to the setting for each client.

Invoice details can be previewed on screen and, if necessary, the details can be amended prior to printing or e-mailing.

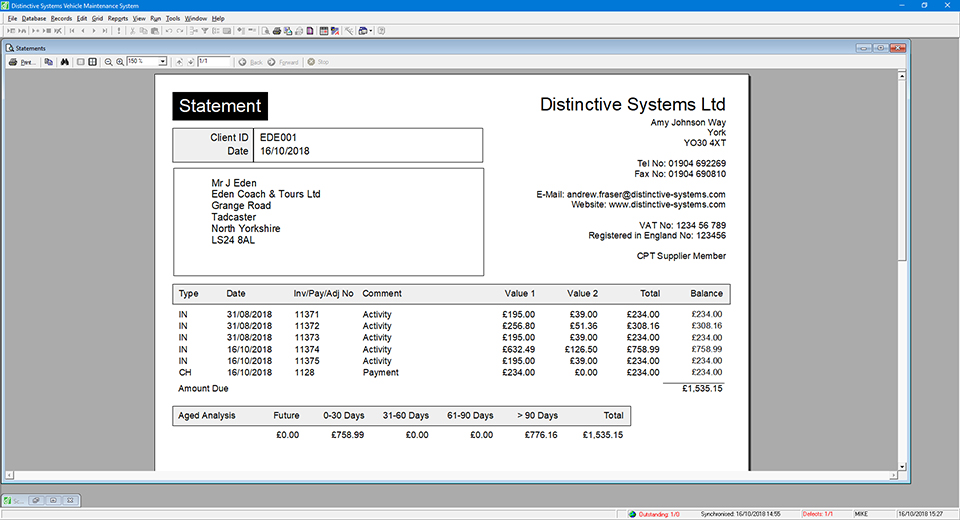

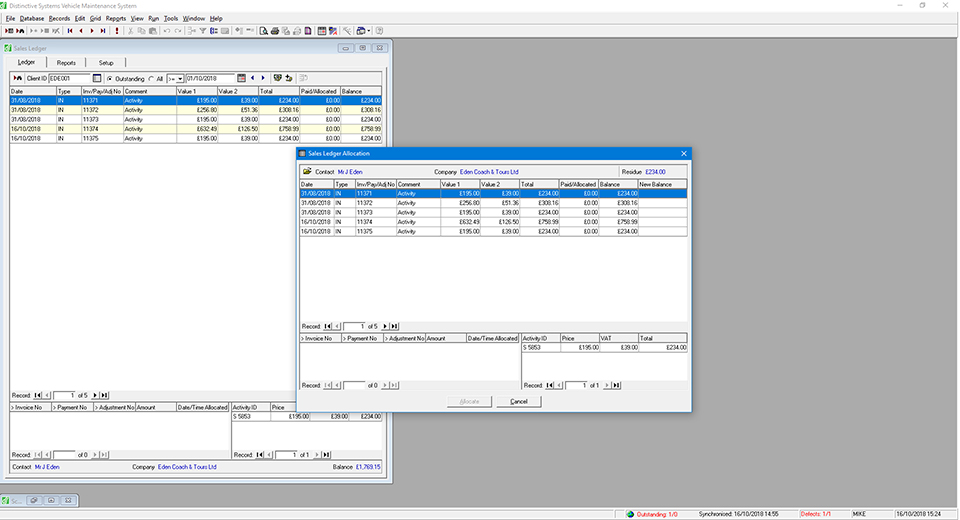

Invoices are posted automatically to the optional VMS sales ledger. The system handles all forms of payment and makes it easy to allocate payments to invoices.

There are extensive reporting facilities including a sales daybook, client statements and an aged debt analysis.

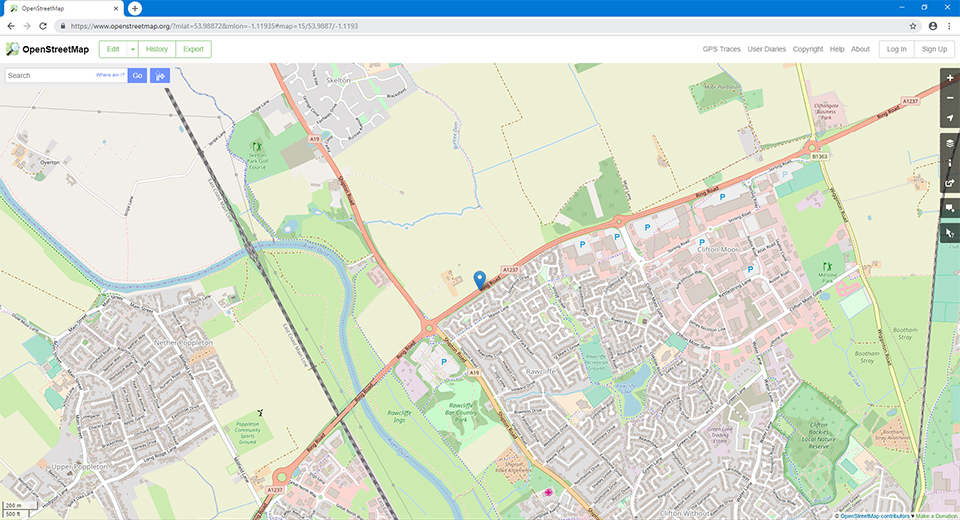

GPS Vendor Integrations

Using our Google Maps Platform integration, it is possible to show the current location of a vehicle directly within VMS. The vehicle location can be displayed from within the Vehicles window by clicking the pushpin button.

To enable this functionality all that is required is to add valid login credentials for the GPS vendor into the VMS setup area and to add a GPS unit ID against each vehicle.

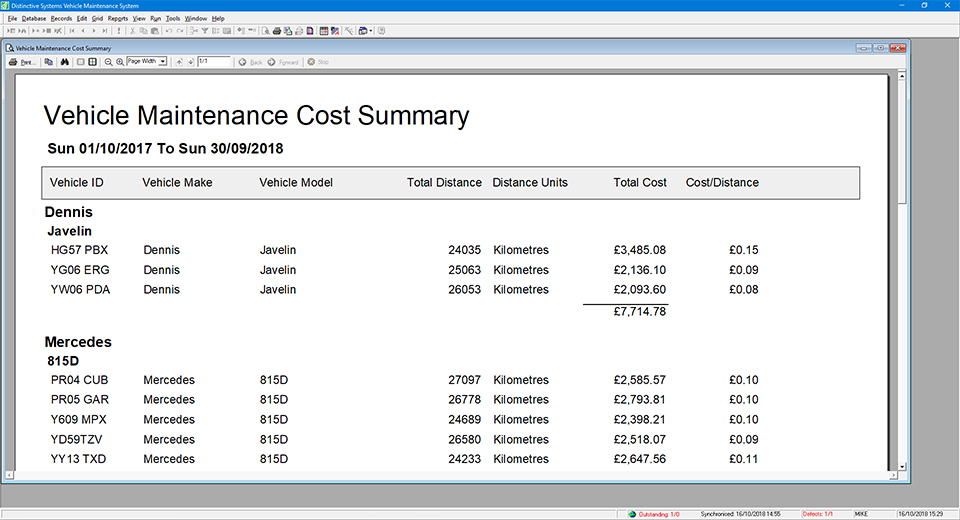

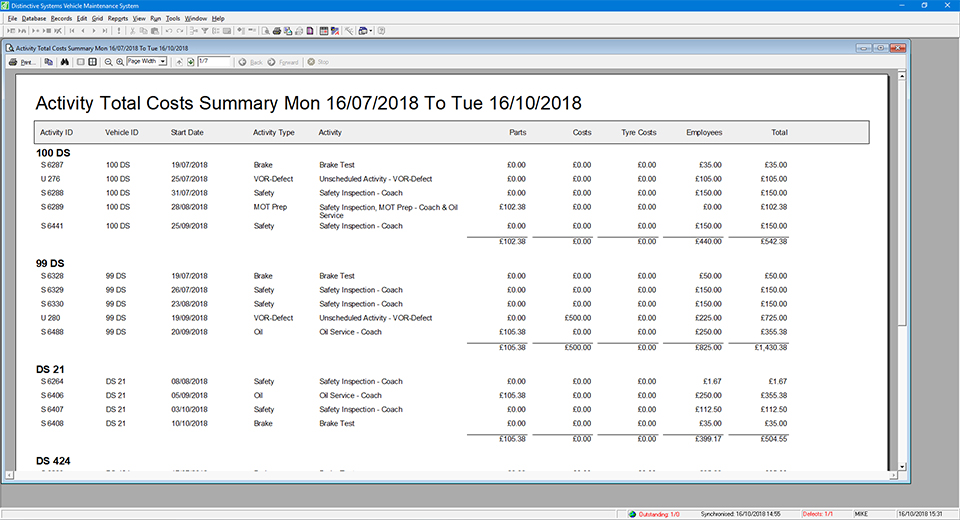

Reports

VMS includes comprehensive standard and user definable reporting facilities throughout the entire system with secure onscreen previews, printed reports and data export. These reports help you meet the necessary standards and ensure compliance.

The vehicle maintenance cost summary report gives the total costs between selected dates with the cost per distance unit displayed for selected vehicles.

The activity history report gives a history of activities between selected dates. The reports can be generated for selected dates and grouped by vehicle ID, make and model and activity type.

There are additional reports to provide detailed analysis of the cost of activities with the ability to group by vehicle makes, models and ID.

Key Features

Vehicles

Comprehensive details of each vehicle can be entered in to the system which includes the vehicle make and model, licence information and test dates.

Employees

Details of each employee can be created in VMS or details can be replicated via the integration from Coach Manager.

Walk-around Check Mobile App

Our award winning Driver Walk-around Check Mobile App is fully integrated with VMS and complies with all statutory walk-around check and defect reporting requirements.

Defect Reporting

The defect reporting system allows user definable defect types, stored common descriptions and a full implementation of the statutory reasons for failure to be used to record defects reported by employees.

Accidents and Incidents

Accidents or incidents can be managed through VMS including the ability to record a detailed description of any damage together with third party information where appropriate.

Activities and Job Cards

In addition to ensuring proper control of all statutory safety issues, VMS also provides a complete solution for operators looking to manage the maintenance of their vehicles for maximum efficiency and longevity.

Electronic Job Cards

The Electronic Job Card not only allows your workshop to become paperless, but also goes way beyond what can be achieved with the original paper document.

Six Month View Planner

The system automatically generates a six month view of scheduled activities which emulates the traditional wall planner.

Activity Diary

The activity diary has the capability of showing activities in both the future and in the past.

Workshop Planner

The highly visual bay planner has a drag and drop facility to allocate activities into user definable bays.

Workshop Optimiser

The graphical workshop optimiser facilitates the smoothing of daily workloads with automated rescheduling of subsequent activities.

Fluid Usage

User definable fluid types can be created within the system and then each time the vehicle is filled the fluid type, amount, cost and employee can be recorded.

Tyre Management

The tyre management module has been designed to manage the maintenance and history recording of individual tyres fitted to vehicles in the fleet.

Stock Control and Warranties

Our optional stock control module is seamlessly integrated into both scheduled and unscheduled activities in VMS.

Invoicing and Sales Ledger

The optional invoicing module has been designed for clients operating a commercial workshop and is also fully integrated with both scheduled and unscheduled activities.

GPS Vendor Integrations

Using our Google Maps Platform integration, it is possible to show the current location of a vehicle directly within VMS.

Reports

VMS includes comprehensive standard and user definable reporting facilities throughout the entire system with secure onscreen previews, printed reports and data export.

companies worldwide

users worldwide

activities handled

A Perfect Fit for Every Operator

VMS has been designed to meet the requirements of the biggest and most demanding operators in the country. It is the result of many tens of thousands of hours of development. As a consequence it includes more features and offers greater flexibility, reliability and performance than anything else on the market.

As we recognise many operators don't require such a comprehensive solution, we offer a simplified Express version of VMS. In addition, to keep within the budgets of many smaller operators, we also offer it in a choice of booking capacities.

We believe this approach offers the best possible solution for every operator. This is especially the case for smaller operators who can take advantage of our keen entry level pricing, yet still be assured they will never outgrow the capabilities of the system.

Express vs. Full

Our Express versions are intended for operators with relatively straightforward needs.

VMS Express can often be suitable for an operator with a small workshop looking to cover no more than the basic requirements for statutory compliance and routine maintenance.

It covers the same ground as the full version, but some features have been simplified or taken out to make it easier to use and much easier to learn.

VMS Express can be upgraded to the full version at any time.

Limited Capacity vs. Unlimited

Our limited capacity versions are there to reduce the cost of ownership for operators with smaller fleet sizes.

By choosing a capacity level that is just sufficient for their current requirements, operators can avoid having to pay for more capacity than they actually need.

Operators can upgrade to the next capacity level as and when their business grows, until ultimately reaching the unlimited capacity level.

Both Express and full versions are available with limited or unlimited capacities.

Microsoft SQL Server Platform

VMS has been developed using Microsoft Visual Studio and the Microsoft SQL Server database engine. SQL Server is part of the Microsoft .NET Platform and is a client/server database. It is the perfect platform for powering both back office and Internet based applications.

Being Microsoft SQL Server based ensures Coach Manager simply doesn't ever go wrong. Day after day, year after year, it just works. It also ensures it doesn't ever run slowly, even for the biggest of operators. Such reliability and performance is only achievable with a Microsoft SQL Server based system.

Best of all, Microsoft SQL Server is entirely free of charge for all but the very largest of operators.

Industry Leading Training and Support

Every member of our training and support team has had several years of real world experience using our software gained while working for one or more of our clients. These include some of the best known and most respected names in the coach industry. As a result every member of the team can explain how to get the best use out of VMS in any given scenario and will make sure it fits seamlessly into your company.

We provide: -

• Comprehensive initial training* at your own offices tailored to the type of work you do and to the needs of your staff

• Unlimited telephone and email support covering every aspect of your ongoing use of our systems

* Charged separately

A Fully Integrated Solution Covering Everything You Do

VMS can not only be used as a standalone system, but can also be combined with Coach Manager or our Tour Booking System, to create the most comprehensive fully integrated enterprise solution on the market.

As vehicles are allocated into the workshop, VMS automatically checks with Coach Manager to ensure there are no conflicting bookings.

As tours or sightseeing trips are created in TBS, they are automatically added to Coach Manager and appear in your diary alongside your charters and contracts.

What Our Clients Say

We have been super impressed with the service from Distinctive systems. From our initial enquiry right through to the implementation, training and support we could not fault the high level of customer experience that we have received. Nothing has been too much trouble and the team have kept us up to date at each stage of set up, they have also supported some of our less computer savvy staff, they have supported training for our accounts team and generally been on hand at the click of a button or a call to answer any questions we have had. Anyone thinking of using Distinctive systems I can highly recommend.

The Coach Manager software by Distinctive Systems is essential to run Dorgan’s Group Vehicles. We also use VMS to manage our own current fleet of 30 vehicles as well as 164 other vehicles which we look after for our Maintenance Management customers. Distinctive Systems software is probably the best available to the coach industry worldwide.

Edwards Coaches Ltd have been using Distinctive Systems software since 1994, DSL supplies probably the best suite of booking software for the coaching industry. From hire to holidays, maintenance to management, service to support, TBS, Coach Manager and VMS are essential tools for us.